Maritime Innovation In Miniature

Olympic Loyalty

This is a model of the crude oil tanker Olympic Loyalty, launched in 1993 and built in the Oppama Shipyard in Japan by Sumitomo Heavy Industries. With a length of 332 metres and a gross tonnage of 160,129 tons she is classed as a supertanker - designated as a VLCC - very large crude carrier. At the time of her launch she was one of the safest oil tankers ever built, an innovative benchmark in the industry, one of the leading ships of a new era of oil tankers.

She was built at a crucial time in the history of oil tanker development and was one of the very first ships built with a double hull, a construction method whereby the bottom and sides of a ship have two complete layers of watertight hull surface: an outer layer which forms the externally visible hull of the ship, and a second inner hull. The second hull forms a barrier if the outer hull is breached by a grounding or low-impact collision.

This safety measure is crucial for the prevention of oil spills and was introduced after a series of accidents involving tankers, culminating in the catastrophic Exxon Valdiz oil spill in 1989. Special legislation was subsequently passed to protect the marine environment.

In 1992 the year that Olympic Loyalty was laid down, the International Convention for the Prevention of Pollution from Ships or ‘MARPOL’ Convention. was amended, making it ‘mandatory for tankers of 5,000 dwt to be fitted with double hulls, or an alternative design approved by the international maritime organisation’.

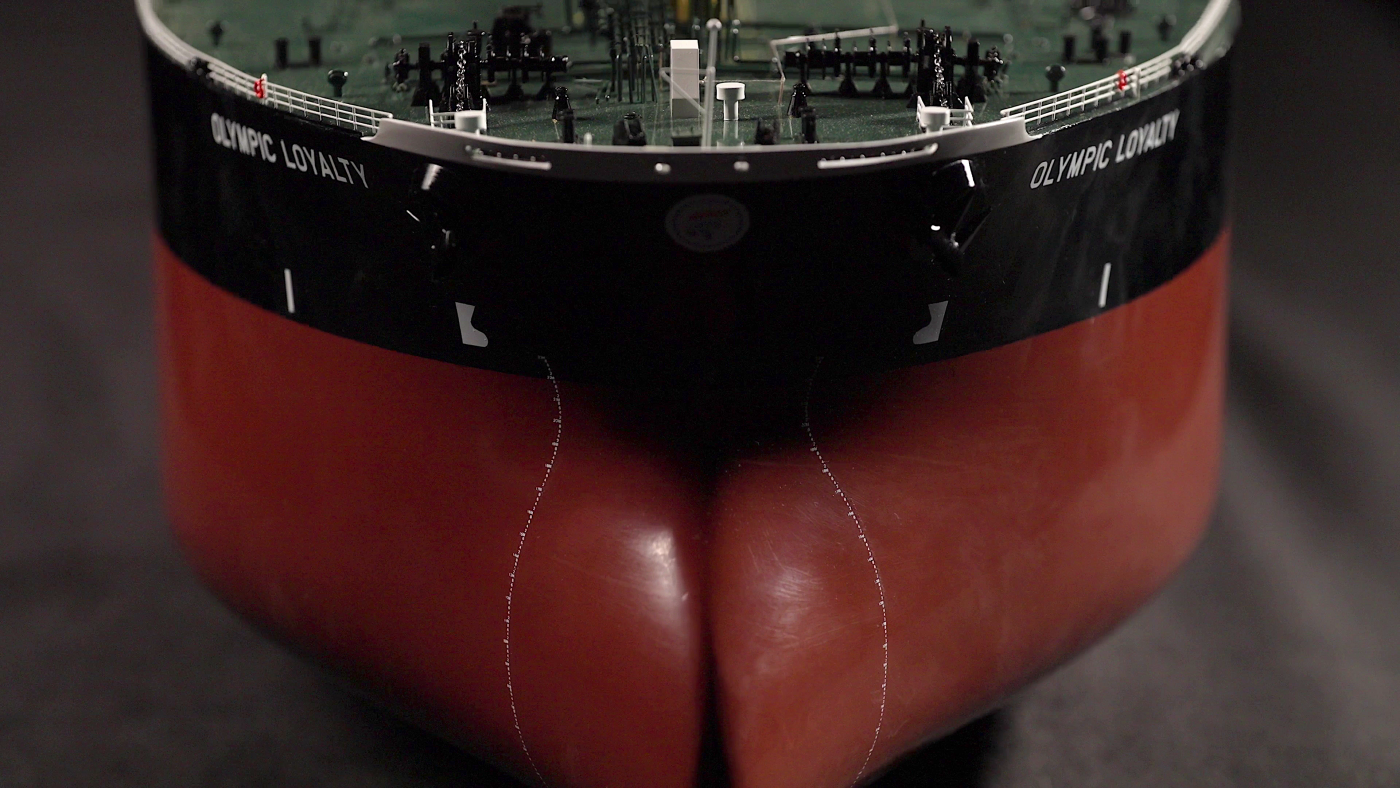

Crude oil carriers transport crude oil from rigs to processing units. Ships like Olympic Loyalty are designed for long-range voyages and to travel at low speeds as the cargo is not perishable. Her hull design reflects this: she is very full in the bow, a design which caters for low speeds and maximum cargo capacity, though this blunt shape leads to increased wave-breaking resistance. To help, she has a bulbous bow to increase the ship’s power efficiency by reducing her wave-breaking resistance.

There are three basic bulb-shapes. This ‘Delta type’ has more volume in the lower half, a design used for ships that frequently change their waterline so that the bulbous bow is immersed regardless of whether she is carrying cargo or not. On the main deck we can see a network of pipelines that are used to load and unload the cargo. Flexible hoses are attached to these permanent pipes. An overflow control system and spill valves ensure that the tanks cannot be over-filled.

A cargo oil heating system maintains the temperature and viscosity of the oil. Without this the oil would become sluggish and thick in cold temperatures. In enclosed storage the oil creates highly flammable vapours which escape the cargo holds through vents on the deck. Firefighting is crucial to the ship’s safety and fire hoses, extinguishers and sprinklers are distributed along the ship’s length and breadth. The ship is also equipped with deck-mounted cranes to handle the cargo oil hoses, but also for the loading, unloading and stowing of supplies crucial to the vessel’s operation.

A helipad allows for easy and regular crew changes and evacuation. The engine room and accommodation are situated towards the stern. She is powered by a Diesel United ‘Sulzer ‘ engine, an engine manufacturer that can trace its roots back to 1898 and created this engine type specifically for the low-speed propulsion of very large crude carriers. They were designed for the lowest possible fuel consumption of the whole operating range from full ahead to slow steaming, whether fully loaded or in ballast, and were renowned for low maintenance costs because of their reliability, durability and the long time between overhauls – up to three years.

The engine produced around 36,000 horsepower to achieve an average maximum service speed around 15 knots with a propeller speed of around 70-79 revolutions per minute. Gearbox problems were eradicated as the RPM of the engine was the same as the propeller.

At the time of her launch Olympic Loyalty was almost unique, but by the end of the decade oil tankers bult to the safety standards used in her construction were the norm – and the protection of the marine environment from oil spills prioritised by the shipping industry, but still far from guaranteed.